What is Enameling?

|

Enameling is melting glass onto metal. This is done by applying the grains of enamel (it often resembles sand but with lots of colors ) and heating it with either a kiln or a torch until the grains melt and join together, forming a layer of enamel (glass) bonded to the surface of the metal.

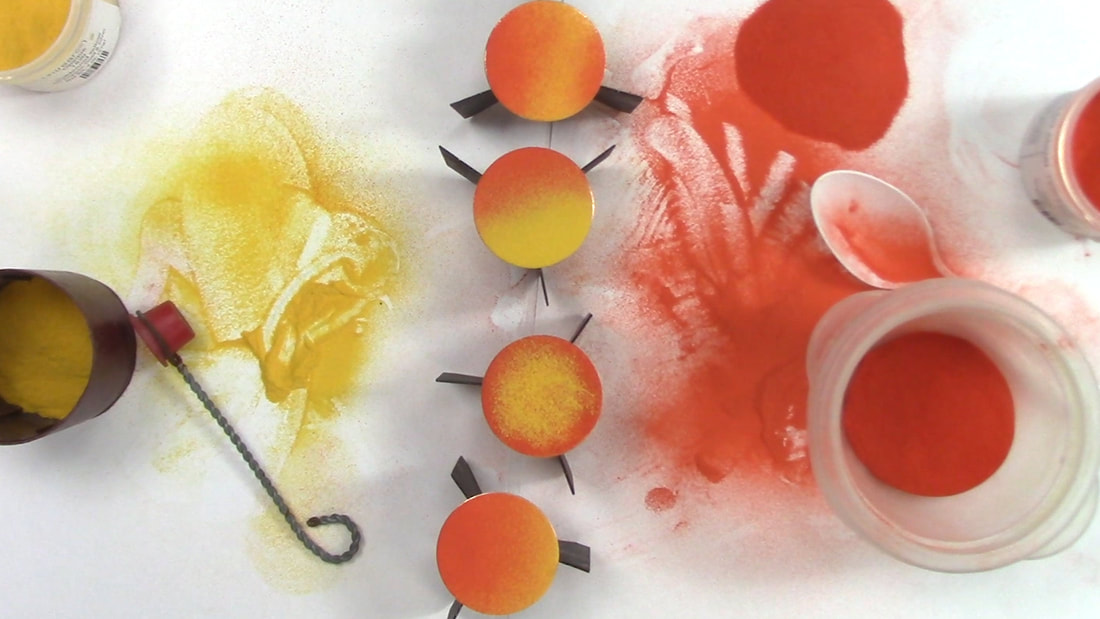

Enamel can be opaque, transparent, or opalescent (semi- see through). Metals used are traditionally silver, copper, and gold, though enamel can be bonded to other metals also. The enamel grains can be sifted using a screen mesh or painted using a paintbrush. Layers of enamel can be applied over each other to create a never-ending variety of colors, textures, patterns, and gradations. The background metal can be textured to allow light to reflect back through the enamel layers creating magnificent effects. Enamels are usually fired at approximately 1350 degrees F- 1500 degrees F. The firing time itself is usually short; anywhere from 1-2 minutes for a smaller piece, and slightly more for a larger one. The desired result of the enamel process (how you want it to look) will dictate the firing temperature and firing time. |

Sifted enamel ready for firing

|

Torch Fired Enamel Video

What is Cloisonne´ Enameling?

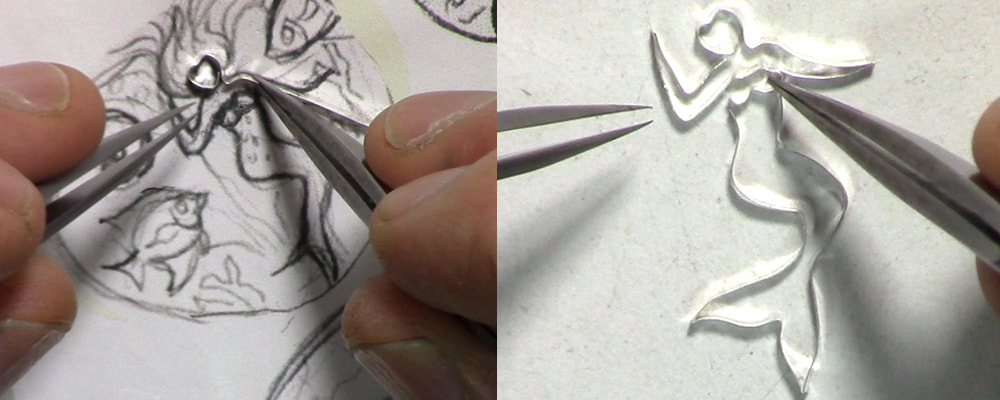

Cloisonne´refers to the technique of enameling using a wire ribbon to separate areas of enamel. Traditionally, a network of wires are bent using tweezers and pliers to create a "drawing in wire". This is fired onto a metal background.

Next, enamel layers are painted within the wire cells, fired, and then this process is repeated until the desired colors are achieved. The layers are applied and fired until the height of the enamel reaches the height of the wirework, and then the piece is ground level so that all are at the same level. A variety of finishing techniques can then be applied to create different looks (glossy, matt, etc.). A single enamel piece may require anywhere from 4 layers up to 20 layers or more, depending on the depth and details desired.

Next, enamel layers are painted within the wire cells, fired, and then this process is repeated until the desired colors are achieved. The layers are applied and fired until the height of the enamel reaches the height of the wirework, and then the piece is ground level so that all are at the same level. A variety of finishing techniques can then be applied to create different looks (glossy, matt, etc.). A single enamel piece may require anywhere from 4 layers up to 20 layers or more, depending on the depth and details desired.